Demand Analysis

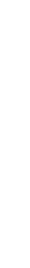

The main causes of power cable line failure: According to statistics, power cable line failure (70 ~ 80)% occurred in the cable accessories (joints and terminals), and the failure rate of the intermediate joints is higher. Including the joints and accessories body quality problems, installation defects, environmental (water, dust, etc.) impact, in the cold and hot weather extreme load operation, the joints localized heat, accessories to accelerate thermal aging and lead to insulation degradation, under certain conditions induced breakdown faults.

Working Principle

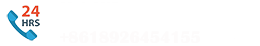

10KV-110KV cable mold injection joint technology (MRJ), is based on the principle of cross-linked polyethylene cable body structure, in the truncated

Cable site production, the use of cable raw materials, based on the structure of the continuation of the layer to restore the connection, the scene regeneration of a new cable. Molded-Reinforced Jointing (MRJ)

The technology melts and combines the cable body structure to form a shield body without stress cone and active interface with consistent essential characteristics. The main solution

Core technical problems.

(1) No microscopic air (gap) between the cable insulation and joint insulation, shielding layer, to restore the intrinsic insulation properties.

(2) MRJ and cable combined as equivalent electrical properties, and cable field strength distribution consistent, eliminating any renewable electrical stress

structural factors.

(3) Identical and stable physical and chemical properties.

(4) Durable safety and reliability.

Third, the functional characteristics

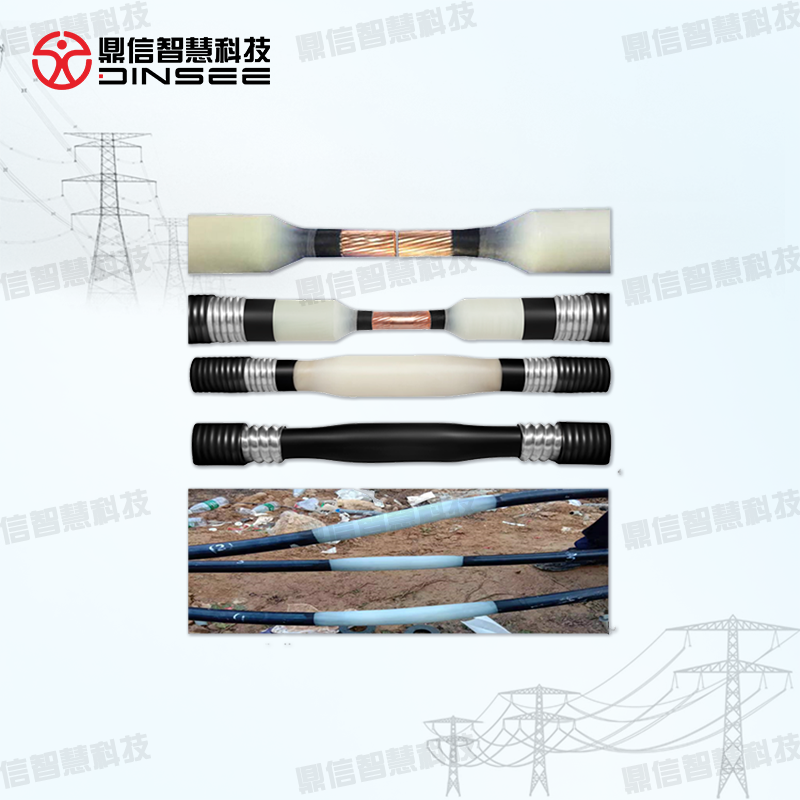

1, conductor connection performance: conductor using exothermic welding technology, conductor isometric, low-resistance, high-strength, welding point never aging, withstand the fault current impact and long-term high-current operation, electrical connections

Durable and reliable electrical connection. The ratio of tensile breaking force of the conductor welding place to the body is 91.2%, and the tensile strength of the conductor joint reaches more than 90% of the strength of its body.

2, electric field stress control: MRJ according to the original cable conductor shielding and outer shielding structure, specifications and the same material to restore the production of conductor shielding layer and insulation shielding layer, to realize the MRJ and the original cable to a continuous, equivalent matching cable electric field shielding body.

Effectively match the cable electric field shielding body, so that the electric field distribution and electric field strength in the natural state, highlighting the MRJ electrical stability and operational reliability.

3、Insulation:Using the same XLPE as the cable insulation to recover, MRJ insulation and cable insulation without air gap interface fusion bonding, structurally forming a consistent whole with the cable without obvious joint characteristics.

Insulation strength is consistent with the original cable, with higher electrical insulation and stable operation of the durability of performance.

4、Performance of mechanical strength: copper core fusion bonding, the repair of the cable can be bent, without worrying about the impact of cable dragging.

5, waterproof performance: field layered injection melt, inside and outside the semi-conductor, insulation body and the original cable seamless fusion bonding, no interface, good waterproof performance.

6, the construction environment: the ambient temperature and humidity requirements are not high (due to the mold core cavity has a high temperature control);.

7、Application scope: two cable connection length is insufficient, MRJ in the length of less than 20cm distance case, can increase the conductor using exothermic welding to renew the conductor, so as to achieve the production of a

MRJ connector can complete the power supply, reducing the cost of cable investment.

8, the external dimensions: and cable diameter is approximately equal or equal to the diameter of the production, and can be made in the MRJ cable bends, overhead suspension of the special location, does not take up too much space for use.

*** Translated with www.DeepL.com/Translator (free version) ***